A demand-driven Supply Chain is a strategic approach to supply chain management that focuses on aligning supply chain processes and resources with actual customer demand signals, rather than traditional forecast-driven or push-based methods. In a demand-driven supply chain, the flow of materials, information, and resources is driven by customer demand signals and market dynamics, enabling businesses to respond quickly to changes in customer requirements, minimize excess inventory, and improve overall supply chain efficiency and responsiveness.

Key Concepts

- Demand Sensing: Demand-driven supply chains utilize advanced demand sensing techniques, such as real-time data analytics, point-of-sale (POS) data, and demand forecasting algorithms, to capture and analyze customer demand signals, market trends, and sales patterns, enabling businesses to anticipate demand fluctuations and adjust production, inventory, and distribution accordingly.

- Demand-Driven Planning: Demand-driven supply chains employ demand-driven planning methodologies, such as demand-driven material requirements planning (DDMRP) and demand-driven replenishment (DDR), which prioritize customer orders and actual demand signals over static forecasts or projections, to drive inventory management, production scheduling, and procurement decisions based on real-time demand signals and supply chain constraints.

- Customer-Centricity: Demand-driven supply chains prioritize customer satisfaction and responsiveness by aligning supply chain processes, capabilities, and performance metrics with customer expectations, preferences, and service level agreements (SLAs), to ensure timely delivery, product availability, and order fulfillment, while minimizing stockouts, backorders, and lead times.

Benefits of Demand-Driven Supply Chain

Demand-driven supply chains offer several benefits for businesses and supply chain stakeholders:

- Improved Customer Service: Demand-driven supply chains enhance customer service and satisfaction by aligning supply chain processes with actual customer demand signals, enabling businesses to deliver products on time, in full (OTIF), and with high quality, while minimizing stockouts, shortages, and delays.

- Reduced Inventory Levels: Demand-driven supply chains optimize inventory levels and reduce excess inventory by aligning production, procurement, and distribution with actual demand signals and consumption patterns, enabling businesses to minimize carrying costs, obsolescence, and write-offs, while improving inventory turnover rates and cash flow.

- Enhanced Agility and Responsiveness: Demand-driven supply chains increase agility and responsiveness by enabling businesses to quickly adapt to changes in customer demand, market conditions, and supply chain disruptions, through real-time demand sensing, dynamic inventory management, and flexible production and distribution networks, to mitigate risks and capitalize on opportunities.

Challenges in Demand-Driven Supply Chain

Despite its benefits, demand-driven supply chain management poses certain challenges and complexities for businesses:

- Data Accuracy and Integration: Demand-driven supply chains rely on accurate and integrated data sources, including sales data, inventory data, and supply chain performance metrics, which may be fragmented, inconsistent, or outdated, requiring investments in data analytics, integration platforms, and master data management (MDM) solutions to ensure data accuracy and reliability.

- Supply Chain Visibility: Demand-driven supply chains require end-to-end visibility and transparency across the entire supply chain, including suppliers, manufacturers, distributors, and customers, to capture and share real-time demand signals, inventory levels, and production status, which may be hindered by data silos, legacy systems, and information asymmetry, requiring collaboration platforms, supply chain visibility tools, and digital ecosystems to enhance visibility and collaboration.

- Demand Volatility: Demand-driven supply chains operate in dynamic and volatile market environments, where demand patterns, customer preferences, and market trends may change rapidly and unpredictably, requiring businesses to continuously monitor and analyze demand signals, adjust production plans, and optimize inventory levels in response to changing conditions, to avoid stockouts, excess inventory, or lost sales opportunities.

Strategies for Effective Demand-Driven Supply Chain

To overcome challenges and maximize the benefits of demand-driven supply chain management, businesses can adopt several strategies:

- Advanced Analytics and AI: Leverage advanced analytics, machine learning, and artificial intelligence (AI) algorithms to analyze demand data, forecast demand patterns, and identify demand drivers, enabling businesses to improve demand sensing accuracy, optimize inventory levels, and enhance demand-driven decision-making across the supply chain.

- Collaborative Planning and Execution: Foster collaboration and alignment among supply chain partners, including suppliers, manufacturers, distributors, and customers, through joint planning, shared forecasts, and coordinated execution, to synchronize supply and demand, reduce lead times, and improve overall supply chain performance and resilience.

- Supply Chain Orchestration: Implement supply chain orchestration platforms and digital supply chain networks that enable real-time visibility, collaboration, and decision-making across the end-to-end supply chain, enabling businesses to respond quickly to changes in demand, optimize inventory allocation, and streamline order fulfillment processes, while enhancing agility and responsiveness.

Real-World Examples

Demand-driven supply chain practices are implemented by leading organizations across industries and regions:

- Procter & Gamble (P&G): P&G operates a demand-driven supply chain that utilizes advanced analytics, demand sensing algorithms, and collaborative planning processes to optimize inventory levels, improve forecast accuracy, and enhance customer service, enabling the company to respond quickly to changes in consumer demand and market trends, while minimizing stockouts and excess inventory.

- Unilever: Unilever leverages demand-driven supply chain practices to streamline production planning, optimize inventory levels, and reduce lead times across its global supply chain network, enabling the company to improve service levels, reduce costs, and enhance sustainability by minimizing waste and resource consumption throughout the supply chain.

- Amazon: Amazon employs demand-driven supply chain strategies to manage its e-commerce operations, where real-time demand sensing, dynamic pricing, and automated replenishment algorithms enable the company to optimize inventory allocation, improve order fulfillment speed, and enhance customer satisfaction, while maximizing revenue and profitability.

Conclusion

A demand-driven supply chain is a strategic imperative for businesses seeking to enhance customer satisfaction, reduce inventory costs, and improve supply chain agility and responsiveness in today’s dynamic and competitive marketplace. By aligning supply chain processes with actual customer demand signals, leveraging advanced analytics and collaboration platforms, and fostering a customer-centric culture, businesses can overcome challenges and unlock opportunities in demand-driven supply chain management, to achieve operational excellence, competitive advantage, and sustainable growth in today’s digital economy. Despite the complexities and uncertainties inherent in demand-driven supply chain management, businesses that prioritize data-driven decision-making, collaboration, and agility are well-positioned to thrive in an increasingly volatile and unpredictable business environment.

Connected Business Concepts And Frameworks

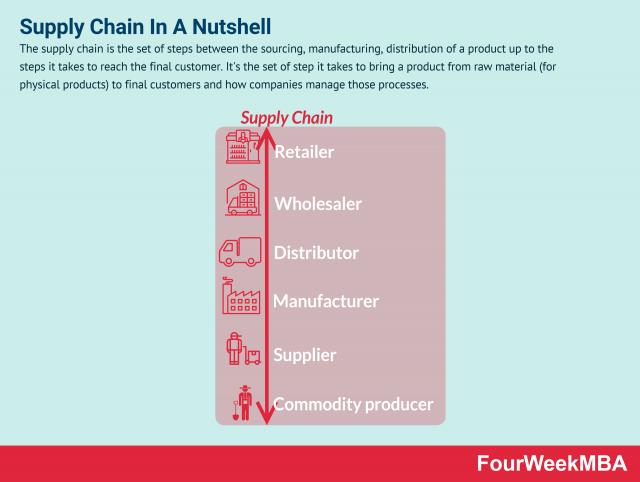

Supply Chain

Data Supply Chains

Distribution

Distribution Channels

Vertical Integration

Horizontal vs. Vertical Integration

Horizontal Market

Vertical Market

Entry Strategies

Backward Chaining

Market Types

Market Analysis

Decoupling

Disintermediation

Reintermediation

Coupling

Bullwhip Effect

Dropshipping

Consumer-To-Manufacturer