A resilient Supply Chain is one that possesses the flexibility, redundancy, and adaptability to withstand disruptions and recover quickly from unforeseen events while maintaining operational continuity and minimizing negative impacts. Resilient supply chains are essential for businesses to withstand disruptions, adapt to changing conditions, and maintain operations in the face of challenges.

Key Components:

- Flexibility: The ability to adjust quickly to changes in demand, supply, or market conditions without significant disruptions.

- Redundancy: Having alternative sources of supply, production, or distribution to mitigate risks and ensure continuity of operations.

- Adaptability: The capacity to respond effectively to unexpected events, such as natural disasters, geopolitical shifts, or supply chain disruptions.

- Visibility and Transparency: Clear visibility into supply chain processes, inventory levels, and supplier performance to identify risks and make informed decisions.

- Collaboration and Communication: Strong relationships and effective communication channels with suppliers, partners, and stakeholders to coordinate responses and mitigate disruptions collectively.

Importance of Resilient Supply Chains

Resilient supply chains offer several benefits to businesses:

- Risk Mitigation: Reduce the likelihood and impact of disruptions, such as supplier failures, natural disasters, or geopolitical events.

- Operational Continuity: Maintain business operations and customer service levels even during challenging circumstances.

- Competitive Advantage: Gain a competitive edge by demonstrating reliability, responsiveness, and agility in the marketplace.

- Customer Satisfaction: Enhance customer satisfaction by minimizing delays, stockouts, and disruptions in product availability.

Challenges in Building Resilient Supply Chains

Building resilient supply chains can be challenging due to various factors:

- Complexity: Modern supply chains are complex, involving multiple stakeholders, global networks, and interconnected processes, making it difficult to identify and manage risks effectively.

- Uncertainty: Uncertain demand patterns, geopolitical tensions, and disruptive events such as pandemics or natural disasters add complexity and unpredictability to supply chain planning and management.

- Cost: Building redundancy, flexibility, and resilience into supply chains may involve additional costs, such as maintaining excess inventory or investing in alternative production facilities.

- Information Sharing: Limited visibility and transparency across supply chain partners can hinder collaboration, communication, and information sharing, making it challenging to coordinate responses to disruptions.

Strategies for Building Resilient Supply Chains

To enhance supply chain resilience, businesses can implement the following strategies:

- Risk Assessment and Management: Identify potential risks, assess their likelihood and impact, and develop mitigation plans to address them proactively.

- Diversification of Suppliers and Partners: Establish relationships with multiple suppliers, manufacturers, and logistics providers to reduce dependency on single sources and enhance supply chain flexibility.

- Inventory Optimization: Maintain optimal inventory levels to buffer against fluctuations in demand, supply disruptions, or lead time variability while minimizing holding costs.

- Technology Adoption: Leverage digital technologies such as IoT sensors, blockchain, and predictive analytics to improve supply chain visibility, traceability, and responsiveness.

- Collaborative Relationships: Foster collaboration and trust among supply chain partners through open communication, shared risk management, and joint problem-solving.

Real-World Examples of Resilient Supply Chains

- Zara: The fast-fashion retailer Zara maintains a highly responsive and agile supply chain that enables it to quickly adapt to changing fashion trends and customer preferences. By producing smaller batches of clothing and leveraging local manufacturing facilities, Zara reduces lead times and inventory risks.

- Toyota: Toyota’s renowned “just-in-time” production system emphasizes lean manufacturing principles, minimizing inventory levels and maximizing production flexibility. By establishing close relationships with suppliers and implementing robust risk management practices, Toyota has built a resilient supply chain capable of withstanding disruptions.

- IKEA: IKEA invests in supplier diversification, sourcing materials from multiple regions to mitigate risks associated with geopolitical instability or natural disasters. Additionally, IKEA collaborates closely with suppliers to ensure ethical and sustainable practices throughout its supply chain, enhancing resilience and reputation.

Conclusion

Resilient supply chains are critical for businesses to navigate uncertainties, mitigate risks, and maintain operational continuity in an increasingly complex and volatile global environment. By embracing flexibility, redundancy, adaptability, and collaboration, organizations can build supply chains capable of withstanding disruptions and delivering value to customers consistently. While challenges exist, the benefits of resilient supply chains—including risk mitigation, operational continuity, competitive advantage, and customer satisfaction—far outweigh the costs of implementation. As businesses continue to prioritize resilience in their supply chain strategies, they can strengthen their ability to thrive in an ever-changing world.

Key Takeaways:

- Definition of Resilient Supply Chains: They possess flexibility, redundancy, and adaptability to withstand disruptions and recover quickly while maintaining operational continuity.

- Key Components: Flexibility, redundancy, adaptability, visibility, transparency, collaboration, and communication are crucial for building resilient supply chains.

- Importance: Resilient supply chains mitigate risks, ensure operational continuity, provide a competitive advantage, and enhance customer satisfaction.

- Challenges: Complexity, uncertainty, cost, and information sharing pose challenges in building resilient supply chains.

- Strategies for Building Resilience: Risk assessment and management, diversification of suppliers, inventory optimization, technology adoption, and collaborative relationships are essential strategies.

- Real-World Examples: Zara, Toyota, and IKEA demonstrate how companies build resilient supply chains through responsiveness, lean manufacturing, supplier diversification, and collaboration.

- Conclusion: Resilient supply chains are critical for navigating uncertainties, mitigating risks, and maintaining operational continuity in a complex global environment. By embracing key components and strategies, businesses can thrive in the face of disruptions and deliver value consistently to customers.

Connected Business Concepts And Frameworks

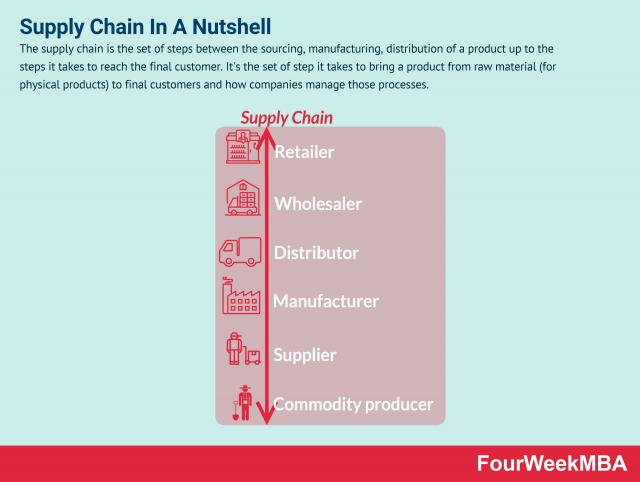

Supply Chain

Data Supply Chains

Distribution

Distribution Channels

Vertical Integration

Horizontal vs. Vertical Integration

Horizontal Market

Vertical Market

Entry Strategies

Backward Chaining

Market Types

Market Analysis

Decoupling

Disintermediation

Reintermediation

Coupling

Bullwhip Effect

Dropshipping

Consumer-To-Manufacturer

Transloading