Junior Mining Networ… · 21:12 19 Apr 2024

Roverpass · 20:48 19 Apr 2024

In today’s dynamic travel landscape, launching a small RV park presents an exciting opportunity to tap into the growing trend of road travel and outdoor living. As more individuals and… Read More

Improving Your Small… · 20:28 19 Apr 2024

Ever dreamt of being your own boss, calling the shots, and building something from the ground up? That dream can become reality by buying a small business. The freedom and challenge of runni… Read More

Pastor Miquéias Tiag… · 19:58 19 Apr 2024

Reprodução: Instagram O fim do casamento de 15 anos entre o cantor Belo e a musa fitness Gracyanne Barbosa abalou as redes sociais na última semana. A not&iacu… Read More

Traffic Bot

Bespoke Yacht Charter

Online wholesale shops from China

eMAG BLACK FRIDAY

420 Coupon Codes

Gardening, Home & Wellness

Casino Backlinks

Actors' day

Digital Marketing Blog | Solkri Design | Full Serv

I migliori casino online con slot gratis

SMM Panel

Rent a yacht for Cannes Festivals and Events

London Escorts

Longevity Review

FireStorm Webhosting | Schweizer Webhosting mit Webshop, Mailhosting, vServer und Rootserver Provider | Schnelle schweizer Cloud Server

สมัคร gclub เว็บตรง, สมัครจีคลับ, gclub เว็บตรง

สมัคร gclub เว็บตรง, สมัครจีคลับ

Tem Teknoloji - Online Alışveriş Platformu

Best Printers Under 10000 in India

https://www.bigjqk.com/

Bespoke Yacht Charter

Online wholesale shops from China

eMAG BLACK FRIDAY

420 Coupon Codes

Gardening, Home & Wellness

Casino Backlinks

Actors' day

Digital Marketing Blog | Solkri Design | Full Serv

I migliori casino online con slot gratis

SMM Panel

Rent a yacht for Cannes Festivals and Events

London Escorts

Longevity Review

FireStorm Webhosting | Schweizer Webhosting mit Webshop, Mailhosting, vServer und Rootserver Provider | Schnelle schweizer Cloud Server

สมัคร gclub เว็บตรง, สมัครจีคลับ, gclub เว็บตรง

สมัคร gclub เว็บตรง, สมัครจีคลับ

Tem Teknoloji - Online Alışveriş Platformu

Best Printers Under 10000 in India

https://www.bigjqk.com/

Newsramp.com Press R… · 19:54 19 Apr 2024

--News Direct--Today, the United Network for Organ Sharing (UNOS) installed a mural by acclaimed artist Hamilton Glass to recognize the far-reaching impact of organ donation and to pay tribu… Read More

Σεφερου Μαρια - Η Αλ… · 19:52 19 Apr 2024

Έσπασε το γλιτσόμετρο από την πίεσ&et… Read More

Hindu God And Goddes… · 19:25 19 Apr 2024

Tithi in Panchang – Hindu Calendar on Saturday, April 27 2024 – It is Krishna Paksha Tritiya tithi or the third day during the waning or dark phase of moon in Hindu calendar and… Read More

Honeysuckle Media · 19:24 19 Apr 2024

Created by the MARY Magazine team, MARY Fest is a celebration of the diversity of cannabis culture. On Saturday, April 20th, this experiential event transforms Scott Studio in Brooklyn into… Read More

Helder Barros · 19:17 19 Apr 2024

«JANAÍNA VIEIRA RENOVA ATÉ 2025 19 DE ABRIL DE 2024 16:00Central de 23 anos está a cumprir a terceira época no Dragão.Janaína Vieira vai… Read More

Tips, News, Updates … · 19:16 19 Apr 2024

Sort Exercise with Python

Write a Python program to sort the elements of the following array in ascending order, using the specified pair-wise dealing method:

Array: [86, 3, 9, 15, 6, 7, 10… Read More

Birsscoupons: Verifi… · 19:09 19 Apr 2024

Surfshark Coupon Code, Promo Code & Deals. Get Up to 70% OFF Surfshark Discount Code On online protection, privacy, security while browsing & more.

About Surfshark… Read More

Informatica Y Tecnol… · 19:08 19 Apr 2024

Software con microservicios La arquitectura de microservicios ha revolucionado la forma en que las empresas desarrollan y despliegan aplicaciones, ofreciendo una alternativa flexible y escal… Read More

Rangeinn · 19:01 19 Apr 2024

A source claims that on Friday, at least twelve people—including some journalists—had their shoes taken from the Parliament House mosque.

Worshippers were shocked to discover tha… Read More

Personal Development · 19:00 19 Apr 2024

Knowledge comes, but wisdom lingers. It may not be difficult to store up in the mind a vast quantity of facts within a comparatively short time, but the ability to form judgments requires th… Read More

Aptgadget.com - Tech… · 18:38 19 Apr 2024

In the rapidly evolving business landscape, technology is not just an enabler but a driver of success. Business owners seeking to stay ahead of the curve must leverage the latest technologic… Read More

Latest Sa Music And … · 18:36 19 Apr 2024

Senior Oat Find You (Radio Edit) ft Alice Orion Mp3 Download

Senior Oat is at it again with yet another irreplaceable banger hit track which have being making serious waves in th… Read More

Atleticanotizie - · 18:36 19 Apr 2024

RICEVIAMO E VOLENTIERI PUBBLICHIAMO Savona, 19 aprile 2024 Un getto del peso di classe mondiale è atteso a Savona per il 13esimo Meeting internazio… Read More

Sports Betting News … · 18:35 19 Apr 2024

Last Updated on April 19, 2024 12:36 pm by Erwin Noguera

The 2024 NBA Playoffs are just around the corner, and fans of the best basketball in the world are anxious to see which teams will em… Read More

Realimagess · 18:34 19 Apr 2024

The Nubia Z60 Ultra NX721J stock ROM firmware is now available for download, and you can download it below. by using this Nubia Z60 Ultra NX721J, such as hang-on logo, FRP lock, fast boot m… Read More

James Doan - My Corn… · 18:34 19 Apr 2024

Aurora, ON (PRLog) While creating an attractive website is necessary, crafting a website that results in conversions is more significant. Without a website that converts, achieving the desir… Read More

Dancehallmag · 18:33 19 Apr 2024

Gyptian‘s 2010 hit Hold You (Hold Yuh) is now certified 2X Platinum in the United Kingdom Read More

Instituto Y Taller D… · 18:33 19 Apr 2024

En el mundo laboral actual, dominar el paquete de Office es casi una necesidad. Ya sea para redactar informes, crear presentaciones impactantes o administrar datos en hojas de cálcul… Read More

Queen Of Treasures · 18:31 19 Apr 2024

Calling all BFFs! Feeling down? Craving laughs and happy endings? Binge-watch your way to bliss with our list of 25 hilarious rom-coms on streaming services. From laugh-out-loud classics to… Read More

Footballflame · 18:29 19 Apr 2024

Nacho Fernandez of Real Madrid in action during the UEFA Champions League quarter-final second leg match between Manchester City and Real Madrid CF at Etihad Stadium on April 17, 2024 in Man… Read More

Tokinomo Brand Activ… · 18:27 19 Apr 2024

In today's competitive marketplace, building a strong brand is essential for success. A well-defined brand not only helps businesses stand out from the crowd but also creates a sense o… Read More

Thought Is Life · 18:10 19 Apr 2024

"నాన్నా ఫలానా స్కూల్లో, 15 రోజులకొ… Read More

Windowthroughtime | … · 18:00 19 Apr 2024

A review of The Case of the Happy Warrior by Christopher Bush – 240313

In delirio veritas. The fear of someone with a secret to hide is that the truth will emerge when their sub… Read More

World Music Views® · 17:58 19 Apr 2024

“Hold You” by Gyptian, released July 16, 2010 has been certified 2x Platinum in the U.K.

The certification was issued on April 19, 2024 for sales and streams surpassi… Read More

Sports News Internat… · 17:37 19 Apr 2024

Formula 1 racing is like a thrilling rollercoaster, and right now, Red Bull Racing is at the heart of all the excitement. Picture this: Max Verstappen, their superstar, is here to stay until… Read More

Open Heavens Daily D… · 17:35 19 Apr 2024

READ >> OPEN HEAVENS 20 APRIL 2024Open Heavens 20 April 2024: [Saturday] Devotional By Pastor E.A. Adeboye — Your NoonREAD PREVIOUS >> OPEN HE… Read More

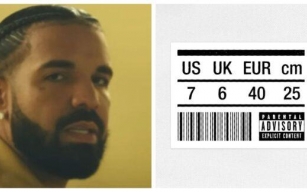

..::that Grape Juice… · 17:18 19 Apr 2024

Drake has officially unleashed his viral diss track, ‘Push Ups.’

The song, which caused all sorts of a flutter when it “surfaced” online, sees Drizzy take aim at a nu… Read More

The Wakefield Doctri… · 17:15 19 Apr 2024

Welcome to the Wakefield Doctrine (the theory of clarks, scotts and rogers)

This is the Doctrine’s contribution to ‘the Unicorn Challenge‘.

Hosted by jenne and ceayr, the… Read More

Notícias Do Futebol … · 17:08 19 Apr 2024

Pivô no futebol: Entenda a tática usada para driblar no campo de futebol

O pivô é uma técnica fundamental de drible no futebol ao vivo. Aprofunde nas melhor… Read More

Performline · 17:00 19 Apr 2024

By Rhonda McGill | April 19, 2024COMPLY is turning 2! To celebrate, we have pulled together a compilation of some of our favorite moments from the last couple of years so that we could high… Read More

The Next Summit · 16:55 19 Apr 2024

DENVER, COLORADO – Recent updates from the National Geodetic Survey (NGS) have fine-tuned the elevations of Colorado’s iconic fourteeners, ensuring… Read More

Políticamente Incorr… · 16:54 19 Apr 2024

Ya es curioso que Irán haya quitado importancia al ataque israelí contra la base de Isfahán, centro de producción de misiles y muy cercana a complejos nucleares… Read More

Courageous Christian… · 16:52 19 Apr 2024

Courageous Christian Father

Mandisa passed away — It is with a heavy heart that we share the news of the passing of Mandisa Hundley, known professionally as Mandisa, a beloved Christia… Read More

Luigi Wewege, President of Caye International Bank on the Rise of Hydrogen: Exploring the Mega Trend

Streetwise Journal · 16:49 19 Apr 2024

As the world leans into a new era of energy, hydrogen is taking center stage, heralded as the next big leap in sustainable fuel. Luigi Wewege, President of Caye International Bank and a reco… Read More

The Natchez Trace Tr… · 16:36 19 Apr 2024

Are you spending too much time and ammunition at the range trying to zero your rifle? If so, you might be one of the many outdoor enthusiasts who struggle with the tedious process of alignin… Read More

Nancy, The Avon Lady… · 16:14 19 Apr 2024

Avon Lady NJ

open your eyes

Lift, lengthen and define with these mascara top picks.

fmg LOVE at 1st Lash Mascara

Lash-loving volumizing and lengthening fibers. With lycopene, olive oil and… Read More

Yakkyofy · 15:44 19 Apr 2024

Thanks to AI, online sellers can now leverage a new tool to avoid getting lost in the crowd and position their products in a unique way

In today’s dynamic e-commerce landscape, info… Read More

Spiritual Prozac · 15:38 19 Apr 2024

Angel friends meet and greet loved ones when they cross the

great divide. Death is the fulfilment of Nature’s plan and obedience to

the laws of Nature that the spirit-life… Read More

Gaceta Guia Inmobili… · 15:33 19 Apr 2024

La jueza del Primer Tribunal Colegiado del Distrito Nacional declaró en rebeldía a José Ernesto Pérez Morales, representante legal de la Iglesia Bautista Vida Ete… Read More

Verysmartinvesting · 15:31 19 Apr 2024

Dow rose 152, advancers over decliners better than 3-1 & NAZ dropped 132. The MLP index advanced 5 to the 281s & the REIT index was up 1+ to the 353s. Junk bond funds wer… Read More

Misteri Dunia Unik A… · 15:26 19 Apr 2024

Kudeta 1953 menggulingkan Perdana Menteri Iran Mohammed Mossadegh

Rep: Umar Mukhtar / Red: Nashih Nashrullah

Foto: EPA-EFE/ABEDIN… Read More

Think · 15:15 19 Apr 2024

Among those with substance use disorders who have been referred to child welfare, less than half received medication or counseling.

Emily Baumgaertner | NYTimes Health | Disclosure Read More

In Defense Of Commun… · 14:38 19 Apr 2024

A fabrication of Nazi Minister of Propaganda Dr Joseph Goebbels, the “Soviets did it” version of the Katyn Massacre remains for decades a major weapon in the arsenal of anti-comm… Read More

Digital Success Blog · 14:37 19 Apr 2024

In the realm of digital visibility, securing a top position in search engine rankings, such as those on Google, is crucial. However, have you ever inadvertently undermined your own SEO endea… Read More

Pecado Dos Anjos: O … · 14:36 19 Apr 2024

Philippe Etchebest é um chef francês amplamente conhecido por ser o jurado do programa de televisão Top Chef, bem como pelo seu trabalho em outros programas de culin&aacu… Read More

Viaggrego - Rassegne… · 14:31 19 Apr 2024

Francesco Benigno ha dovuto abbandonare l'Isola? Con un post su Instagram la trasmissione lancia la notizia ma lui replica sui social spiegando che lo volevano fuori e per questo gli avrebbe… Read More

Headline News Online · 14:29 19 Apr 2024

The chase for the Stanley Cup is back underway, with the NHL’s top 16 teams left to duke it out through four gruelling rounds.

* This article was originally published here

The post St… Read More

The Art Of Living ..… · 14:28 19 Apr 2024

Are you looking for a clinical trial to help treat your chronic lymphocytic leukemia (CLL)? Find out what you need to know before you sign up.

https://ift.tt/L5KXsBM

from Be Healthy

Always Read More

Socraticgadfly · 14:00 19 Apr 2024

I had already written this up yesterday, but we now have a new top story!Jesse "the Body" Ventura (because his stanners hate that) now says he can beat Biden and Trump. So? Get No Labels or… Read More

Crazyfitnessguy® · 14:00 19 Apr 2024

b'\r\n\r\n\r\n* Affiliate Disclaimer: This page contains some affiliate links. By using these links, you have no additional costs but I will be paid a commission or a discount on the se… Read More

Heavy Metal Rarities · 13:58 19 Apr 2024

Posted by OldNecromancer — Today, 13:58 — Replies 0 — Views 80 Read More

Adore Charlotte - Pa… · 13:55 19 Apr 2024

Have you ever stumbled upon a baby name that looked beautiful on paper but left you scratching your head about its pronunciation? Navigating the tricky waters of baby naming is an art, espec… Read More

Queens Voice · 13:27 19 Apr 2024

Cellphone Thieves Hit Man in Face with Baseball Bat The NYPD is searching for these men in connection with an attack on a Queens man with a Read More

The Movie Waffler · 13:21 19 Apr 2024

A repressed woman becomes obsessed with a teenage boy.Read more >>> Read More

Coisas Judaicas · 13:17 19 Apr 2024

Depois de três dias sem comida ou eletricidade na sala segura do seu Kibutz, enquanto os terroristas do Hamas cometiam as suas atrocidades, a mulher panamenha decide selar o seu… Read More

Navigamus Blog A Vel… · 13:03 19 Apr 2024

Va verso l'epilogo il 33° Campionato Intercircoli, tradizionale manifestazione di vela d'altura genovese programmata ogni anno in primavera grazie all'impegno di un affiatato Comita… Read More

Arrojada Mix · 13:00 19 Apr 2024

Olá pessoal, vamos de dica de maquiagem?Erros Que Destroem Sua MaquiagemVocê já se perguntou por que sua maquiagem nunca da certo? Ou se dá certo, por que ela… Read More

The Latest Popular C… · 12:41 19 Apr 2024

線上看: 哈爾濱一九四四

主演: 秦昊 / 楊冪 / 張子賢 / 欒元Ć… Read More

Carl Jung Depth Psyc… · 12:30 19 Apr 2024

1Your dream is really the stuff artists work with Read More

Fiction From K Brown · 12:25 19 Apr 2024

Most of my readers know, by now, that I spend a certain amount of time on the website DeviantArt. I initially went there with the intention of getting artwork for the covers of some of… Read More

Exploring The Limitl… · 12:24 19 Apr 2024

Anthony Bell - Abstract Artist. Studios in Brazil, Spain and the United Kingdom.

Abstract art stands as a testament to human creativity and the boundless possibilities of artistic expressi… Read More

Promoții Online · 12:12 19 Apr 2024

Descoperă promoții online active în luna Aprilie 2024 în diferite magazine online românești. Verifică zilnic aici dacă au mai fost comunicate noi c… Read More

Essere Informati · 12:02 19 Apr 2024

Israele attacca l'Iran: L'Alba di un Conflitto globale Imminente?Nella quiete dell'aurora, l'escalation tra Israele e l'Iran ha raggiunto un nuovo picco con un presunto attacco lanciato dall… Read More

Art+Science Designs … · 12:00 19 Apr 2024

This is our daily reminder to joyfully pay it forward. International Snow Leopard Day is a day dedicated to celebrating the elusive and majestic snow leopard, the ultimate stealthy feline of… Read More

Updated Daily Free H… · 11:50 19 Apr 2024

The post Wordscapes Answers Daily Puzzle April 20 2024 (4/20/24) appeared first on Your Crossword Answers Read More

Paradise Break · 11:34 19 Apr 2024

Fairfield by Marriott, part of Marriott Bonvoy’s global portfolio of over 30 extraordinary hotel brands, announces its debut in Europe with the opening of Fairfield by Marriott Co… Read More

News24×7 · 10:48 19 Apr 2024

By Remy Tumin from NYT Business https://ift.tt/juQWd27 Read More

Profitfromai - Unloc… · 10:44 19 Apr 2024

The recent escalation in the Iran-Israel war marks a significant uptick in Middle East tensions, underscored by a missile strike launched by Israel on a crucial site in I… Read More

Exaputra · 10:40 19 Apr 2024

Mystery of the Afterlife: Fact and ResearchWhat is Afterlife?The afterlife simply refers to a purported existence that continues after a person's physical death.The question of what lies bey… Read More

Escafandrista Musica… · 10:00 19 Apr 2024

@KimletGordon @matadorrecords Gènere: #rockalternatiu #experimental #cançódeldia La llegenda musical i artista multidisciplinària Kim Gordon torna amb el seu

La e… Read More

South African News · 09:46 19 Apr 2024

Looking to cut back on wine and beer? Consider naltrexone, a pill that can help reduce binge drinking without the need for daily medication or painful injections. Learn how this prescription… Read More

Discover · 09:38 19 Apr 2024

In December, the train began running on its first route through Mexico’s Yucatán Peninsula. On a five-day journey a few months later, the author encountered enthusiasm, and sch… Read More

Curioson · 09:08 19 Apr 2024

Un paseo por la ciencia de los venenos y su presencia en el arte y la ficciónLa historia de los venenos es la historia de la humanidad. Desde la cicuta que acabó con la vida de… Read More

Ppq · 09:07 19 Apr 2024

Eingelöste Wahlversprechen: Mit dem richtigen Zeitausschnitt gelang es dem ZDF zuletzt, einen drastischen Rückgang bei den Strompreisen nachzuweisen.Man weiß es nicht genau… Read More

Clásicos Para Aprend… · 09:07 19 Apr 2024

El Ku Klux

Klan aparece en los Estados Unidos

ya en la época de la Guerra Civil

enfrentando no solo a la población negra

sino también a los judíos y católi… Read More

Handover · 07:13 19 Apr 2024

Logistics industry, which accounts for a

significant 13-14% share in India's gross domestic product (GDP), comes with a

lot of expenses for businesses to bear. These include transportation c… Read More

The Scientific Garde… · 07:00 19 Apr 2024

One of the problems that I have been noticing when growing cucumber varieties is that many of them have been changed over times – most likely through consolidation of what were heirloo… Read More

Pinoybix Engineering · 06:34 19 Apr 2024

Problem Statement: Electrical Engineering Professional Subjects Electric Circuits: AC Circuits Problem Solving An impedance coil has a resistance and inductance of 20 ohms and 0.05 H respect… Read More

Comic Book And Movie… · 06:30 19 Apr 2024

Ryan Reynolds is a fairly popular actor who's probably best known for starring in the Deadpool series of movies, along with playing many other roles seen on the silver screen. But what's his… Read More

Philden Model Railwa… · 05:30 19 Apr 2024

This week, Friday Film Club once more presents the musical genius of Quincas Moreira in the hit film...Don't forget to like and subscribe for your Tropicanza train fix! Read More

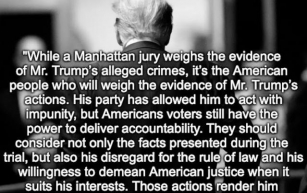

Jobsanger · 05:00 19 Apr 2024